Material of filter element components:

Filter material : Asymmetric gradual aperture polypropylene (PP) plated filter

Supports/Diversion : PP

Core/Cover/End cover/End caps : PP

Sealed leads/Fins : PP,Built in stainless steel

O-Ring : 222,226 silicon rubber etc.

Sealing technology : Hot melt without adhesives

Characteristics and features

All polypropylene structural materials, professional hot-melt sealing technology, no adhesive, no secondary pollution

Excellent high-tem resistance and extensive chemical compatibility

All the compositions reach up to the requirement of the biological testing characteristics of USP Class 6 plastic products at 121℃ and the food contact materials listed in the relevant regulations of Chapter 21 of the Federal Regulations of the United States (CFR). They also conform to the requirements of China's "Standard for Hygienic Safety Evalution of Equipment and Protective Materials in Drinking Water" (2001) for drinking water transport and distribution equipment.

It is manufactured under ISO 9001 and ISO 14001 systems and Class 100 environment.

The filter membrane has a gradient aperture structure for pre-filtration with large flow rate ,low pressure difference and long service life .

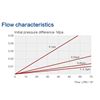

Technical specifications and operating parameters

Size | Diameter: 2.75” (69 mm) Length: 5”/10”/20”/30”/ 40” etc. |

Filtration area | Single 10” filter element is about 0.65m² |

Maximum differential pressure | Positive: 0.4MPa Negative:0.2MPa |

Maximum pressure difference and temperature | Maximum operating temperature: 85 C/0.2 MPa; |

Typical application

Prefilter as terminal sterilizing filter.

Sterilization filtration of LVP, fine needle, freeze-dried and spray dried drug.

Sterilization filtration and Mycoplasma removal filtration of animal serum, liquid medium, buffer solution, supplement water, etc..

Sterilization filtration of vaccines and genetically engineered products.

Sterilization filtration of eye drops, diagnostic reagents, etc.

Sterilization filtration of various process water and pharmaceutical water.

Sterilization filtration of various solvents in pharmaceutical industry.

Pre filtration of draft beer before sterilization.

Terminal filtration of bottled water, draft beer, wine, yellow wine, soft drinks, syrups, etc. in the food and beverage industry.

Filtration of various gases.

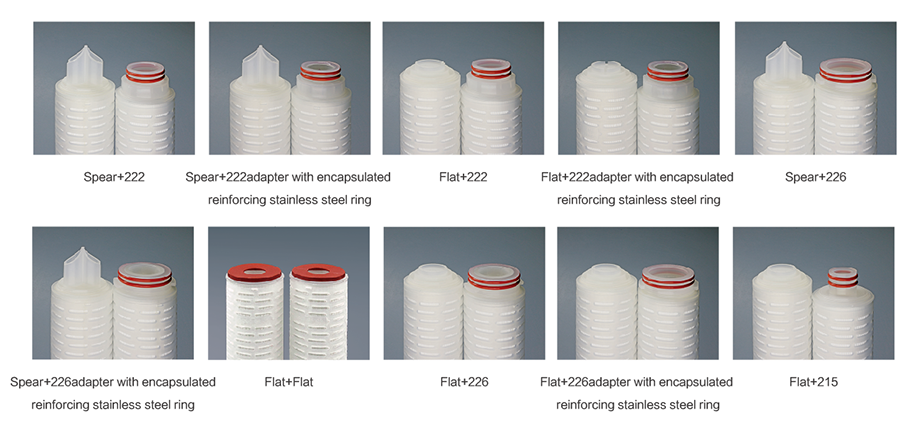

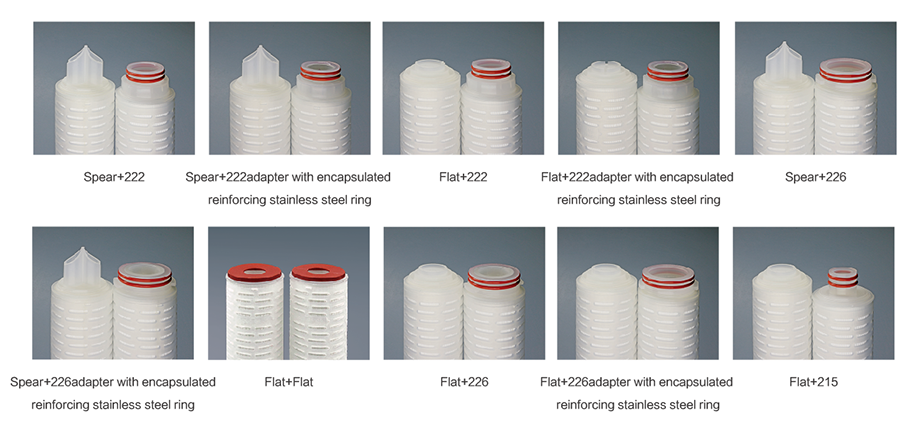

Adapter Style

Ordering information

1 | Membrane | Polypropylene PP flat filter material |

2 | Pore size | 0.04 / 0.1 / 0.22 / 0.45 μm |

3 | Length | 5” / 10” / 20” / 30” / 40” |

4 | Connector/End Cover A/AA/B/BB/C/CC/D/E/EE/F | Spear+222 Spear+222adapter with encapsulated reinforcing stainless steel ring Flat+222 Flat+222adapter with encapsulated reinforcing stainless steel ring Spear+226 Spear+226adapter with encapsulated reinforcing stainless steel ring Flat+Flat Flat+226 Flat+226adapter with encapsulated reinforcing stainless steel ring Flat+215 Spear+3 Flange Bayonet adapter |

5 | Gasket Material S、E、F、FF | S: S silicon rubber E: EPDM rubber F: Fluorine rubber FF: Encapsulated fluoroelastomer |

6 | Application P | Pharmaceutical grade for bio-pharmaceutical&food and beverage industry |

7 | Special Specification Remarks | Standard Specification Default |