Operation Principle

A built-in VHP generator heats up the hydrogen peroxide, converting it from liquid to vapour, then blown into the chamber, creating a lethal environment capable of killing bacteria, viruses and fungi. Each step of the process is fully controlled, guaranteeing perfect performance .

Application

VHP Decontamination Chamber is designed for two different zone of area, for transferring of product from lower classified zone to higher classified zone (Non– sterile area to Sterile area), without effecting the balancing of respective zone, Containment free product transfer to higher classified zone. The Unit is especially suitable for GMP regulated pharmaceutical companies manufacturing drugs aseptically.

Features

Sterilization process <120min to realize multiple sterilization operations one day.

Fully automatic operate, menu can be saved and invoked.

Emergency Stop.

Adopts clean compressing air for vaporization power which can reduce the impact of the pressure differential when taking air from the room.

Decomposition filter can effectively reduce the concentration of VHP remain Reduce the impact on environment and personnel.

Through up down side to reduce the inspection space.

Corner sterilization pass box which will increase factory space utilization ratio, and improve the distribution.

Very low hydrogen peroxide consumption.

VHP: the Process

Air tightness test - Dehumidification - H 2 O 2 Vaporization sterilization - Row of residual - End

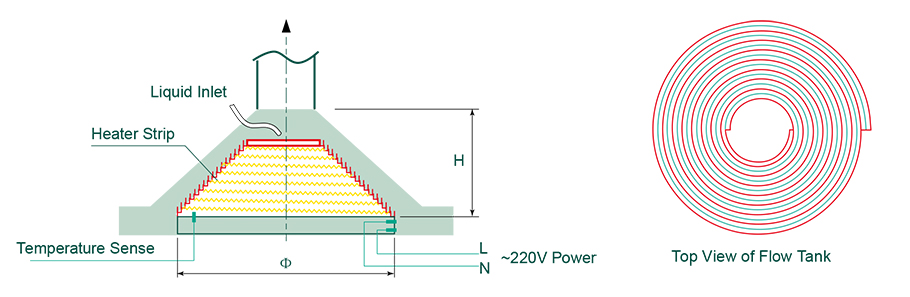

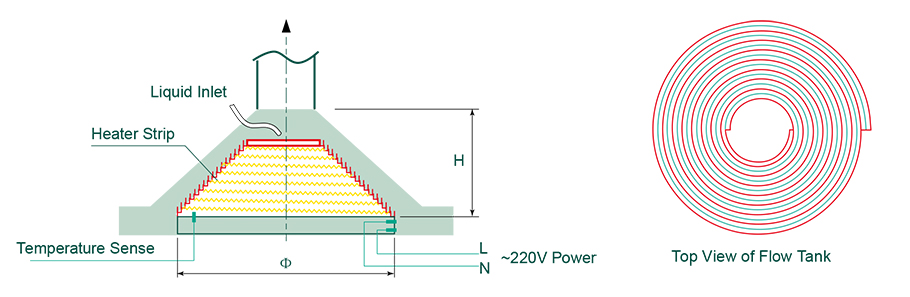

Vaporizer Schematic Draw

Standard size and parameters

Model | Overall size

W×H×D | Work size

W×H×D | Rated capacity

(L) | Working area

clean class | Sterilization

efficacy | Power

(kw) |

LATM288 | 1200×800×2000 | 600×800×600 | 288 | Class B | 6-log | 3 |

LATM512 | 1400×800×2200 | 800×800×800 | 512 |

LATM1000 | 1600×1060×2100 | 1000×1000×1000 | 1000 |

LATM1440 | 1600×1260×2300 | 1000×1200×1200 | 1440 |

Note: specifications listed in below table are only for customers' reference. It is mostly designed and manufactured according to customers' URS.